Process management and monitoring

Our products for Process management and monitoring

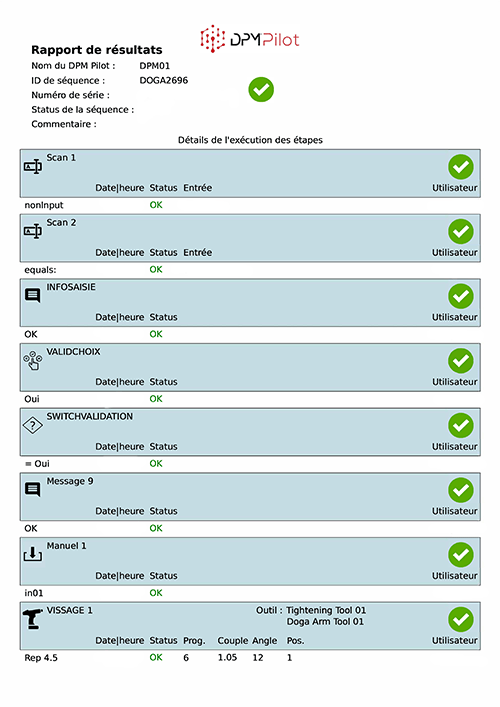

Ensure complete traceability of your tightening results has never been easier with DPM®Pilot

Assembly quality is at the heart of production challenges! The traceability of all operations performed on a product is becoming a standard among major manufacturers. Beyond its process control and assembly operation monitoring, DPM®Pilot is a powerful ally to manage the traceability of your products. Whether linked by a barcode, a manually entered serial number, or an identification number automatically assigned by DPM®Pilot, you will keep track of every performed operation! These results can be directly communicated to your internal production management system or consolidated and formatted through the automatic generation of comprehensive reports.

Assembly quality is at the heart of production challenges! The traceability of all operations performed on a product is becoming a standard among major manufacturers. Beyond its process control and assembly operation monitoring, DPM®Pilot is a powerful ally to manage the traceability of your products. Whether linked by a barcode, a manually entered serial number, or an identification number automatically assigned by DPM®Pilot, you will keep track of every performed operation! These results can be directly communicated to your internal production management system or consolidated and formatted through the automatic generation of comprehensive reports.

Product focus: DPC Touch operator / machine interface

A true conductor, DPC Touch knows how to count, order, control and display an assembly process. Compatible with the vast majority of screwdrivers, it is the ideal sequencer for standalone workstations.