Torque reaction arms and tool positionning system

To guarantee optimal quality and traceability, most DOGA torque reaction arms are available with a positioning system. So every screw is tightened at the right location and at the right torque!

Our products for Torque reaction arms and tool positionning system

The function of positioning

Most DOGA torque reaction arms are available with or without a positioning system. This function, called "Posi-Control" or "PC", is made possible by adding position encoders to the arms. These encoders define the tool's location in space and allow for tightening sequences to be programmed. This system guarantees optimal quality and traceability.

The absolute position encoders are sensing devices that monitor the angular and/or linear movements of the tool.

DOGA torque reaction arms are fitted with from 1 to 4 sensors depending on the model. There are 4 types of position encoders:

• Contactless linear encoders on the longitudinal stroke (BA, BA...C and SLIDER models).

• Contactless angular encoders with magnets (BA, BA...G models).

• Cable encoders that monitor the extended length of the arm. They are used to confirm the distance between the tool and the screw tightening point (DMF models).

• Gyroscopic encoders that measure the arm orientation and assembly tool positioning angle relative to the screw tightening position (DMF models).

The correct combination of these different encoders offers optimal assembly tool positioning relative to the screw tightening position.

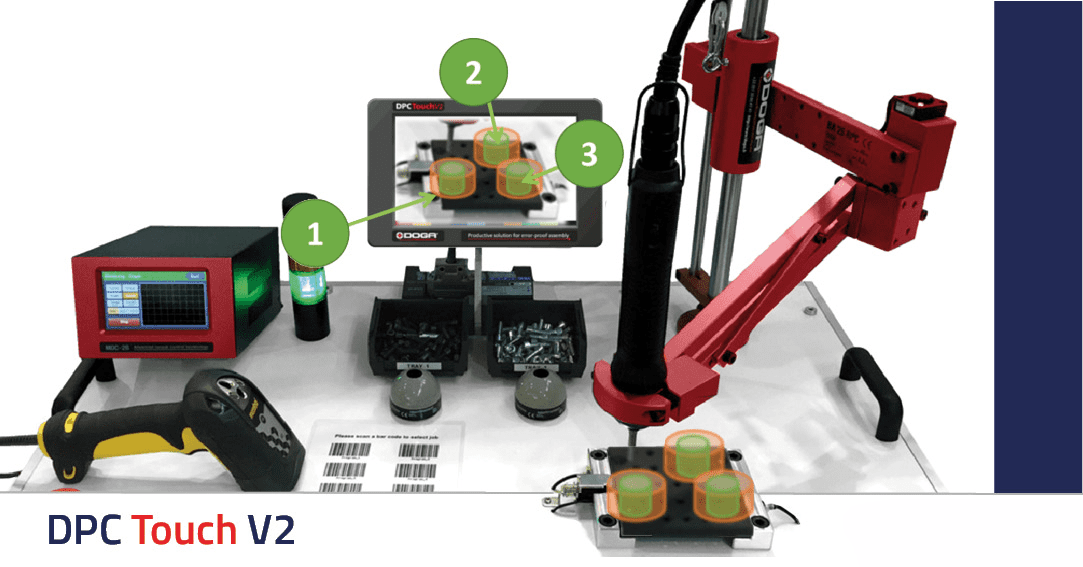

The position encoders of the torque reaction arms, when combined with the DPC Touch V2 (sequencing and assembly process monitoring interface), create a system capable of guiding an operator through complete assembly sequences.

DPC Touch V2 Human Machine Interface

The simultaneous use of the DPC Touch V2, with a torque reaction arm equipped with a positioning sensors, guarantees you optimal quality and traceability for a zero-defect assembly.

How to prevent Musculoskeletal Disorders (MSD)?

Assembly operations are a source of Musculoskeletal Disorders (MSD).

Assembly operations are a source of Musculoskeletal Disorders (MSD).

Did you know that they represent around 85% of declared occupational diseases (source ANACT)?

These disorders affect the health and safety of your operators. In order to lower the risks, measures to reduce the difficulty of tasks can be put into place.

Designing workstations and production lines with improved ergonomics, using torque reaction arms, contributes to the safety and comfort of the operator while meeting the challenges of productivity and quality.

These workstation adjustments not only have a positive effect on the working conditions of operators, but also have a significant impact on quality and productivity.

Ergonomics

These ergonomic workstation solutions eliminate torque reaction in the operator's hand, absorb assembly tool vibrations, lighten the load and assist the operator.

Safety

By carrying out repetitive movements and relieving postural constraints, torque reaction arm protects against possible injuries to joints, tendons and muscles.

Productivity

The benefit of this technology is to increase operational efficiency.

Fluid movement of the axes ensures complete maneuverability and facilitates assembly operations.

Quality

DOGA torque reaction arms are designed to guarantee quality by optimizing assembly tool positioning without oscillation. This results in significant improvements in the finished product.

Premium French manufacturing

Faithful to the values of the French Fab movement, DOGA is committed to the development and manufacture of innovative products with high added value. With 25 years of expertise and know-how, our made in France torque reaction arms meet the high standards you expect and are CE certified. Their flexible and modular design guarantees great flexibility of use and perfect tool balancing.

Faithful to the values of the French Fab movement, DOGA is committed to the development and manufacture of innovative products with high added value. With 25 years of expertise and know-how, our made in France torque reaction arms meet the high standards you expect and are CE certified. Their flexible and modular design guarantees great flexibility of use and perfect tool balancing.

Torque reaction arms provide your operators with optimized operating comfort while ensuring increased productivity.

DOGA designs and manufactures custom torque reaction arms to your specific needs, with virtually no customization limit!

Faithful to the values promoted by the French Fab movement, DOGA takes part of a development process and innovative products manufacturing with high added value.

Which style of reaction system should you use?

Each workstation requires a unique ergonomic design.

To meet these different needs, DOGA has developed the most complete and extensive range of torque reaction systems on the market to optimize the ergonomics of your workstation.

The BA torque reaction systems (linear, articulated and Cartesian)

Specially designed for fixed installations on tabletops or floor mounts, BA torque reaction arms are recommended for applications requiring precise vertical tightening.

SLIDER suspended torque reaction systems

The SLIDER torque arms are designed for use in cramped workspaces. Mounted on overhead frames or rails, they allow you to optimize space on your production line. They are used for vertical tightening applications over a large work areas.

DMF carbon fiber telescoping arms

The DMF telescoping arms are compact and lightweight. They are easily installed on overhead frames, are versatile and allow multidirectional tightening.