DPMPilot process supervision and traceability smart controller

DPMPilot process supervision and traceability smart controller

Designed and manufactured by DOGA, DPMPilot supports you in the deployment of Industry 4.0 in your manufacturing processes. As a true conductor of your assembly station, DPMPilot manages the tools and accessories, guides the operator, and ensures traceability of results.

Benefits

DPM®Pilot controls workstation equipment autonomously through local connections.

• No risk of production downtime due to network or server issues

• Process management information are integrated and always available

DPM®Pilot has been designed to communicate with a variety of brands.

• DOGA, STANLEY©, Tohnichi, Open protocol tools, etc.

• Thanks to DPM®Pilot’s user-friendly interface, configuring your assembly sequences does not require a computer or automation skills.

• DPM®Pilot takes care of the entire process, guides operators, decreases their training time and increases their versatility.

DPM®Pilot saves results locally or remotely.

• Recording of all process datas

• Creation of production reports

Product description

Workstation-oriented design meets requirements of your industrial assembly processes.

|

|

|

|

|

|

|||||||

|

Error

proofing |

Operator

guidance |

Multi-protocol

|

Traceability

|

||||||||

• Compliance with

|

• Improved efficiency

|

• Compatible with

|

• Recording of all

|

||||||||

DPM®Pilot TECHNICAL CHARACTERISTICS

• Operating system: embedded Linux (Linux Kernel 5.2)

• x 4 inputs and x 4 integrated 24 V digital outputs

• x 2 separate networks:

- x 1 WAN network port for external network connection

- x 4 LAN network ports for connecting tools and accessories

• Suitable with high-definition or standard touch screens with HDMI connection

• Storage capacity available for the application: 128 GB

(for sequences between 3.5 and 5 MB and 150 KB results files)

- Storage example 1: 50 sequences and 850,000 results

- Storage example 2: 1,000 sequences and 820,000 results

• x 2 USB ports (expandable with external USB switch) for printer, barcode scanner, badge reader, etc.

• Up to 20 connected tightening tools

• x 8-inputs, x 8-outputs extension with the add-on DPM I/O Module (up to 2 add-on module)

• Up to 2 connected analog position control DigiLink modules

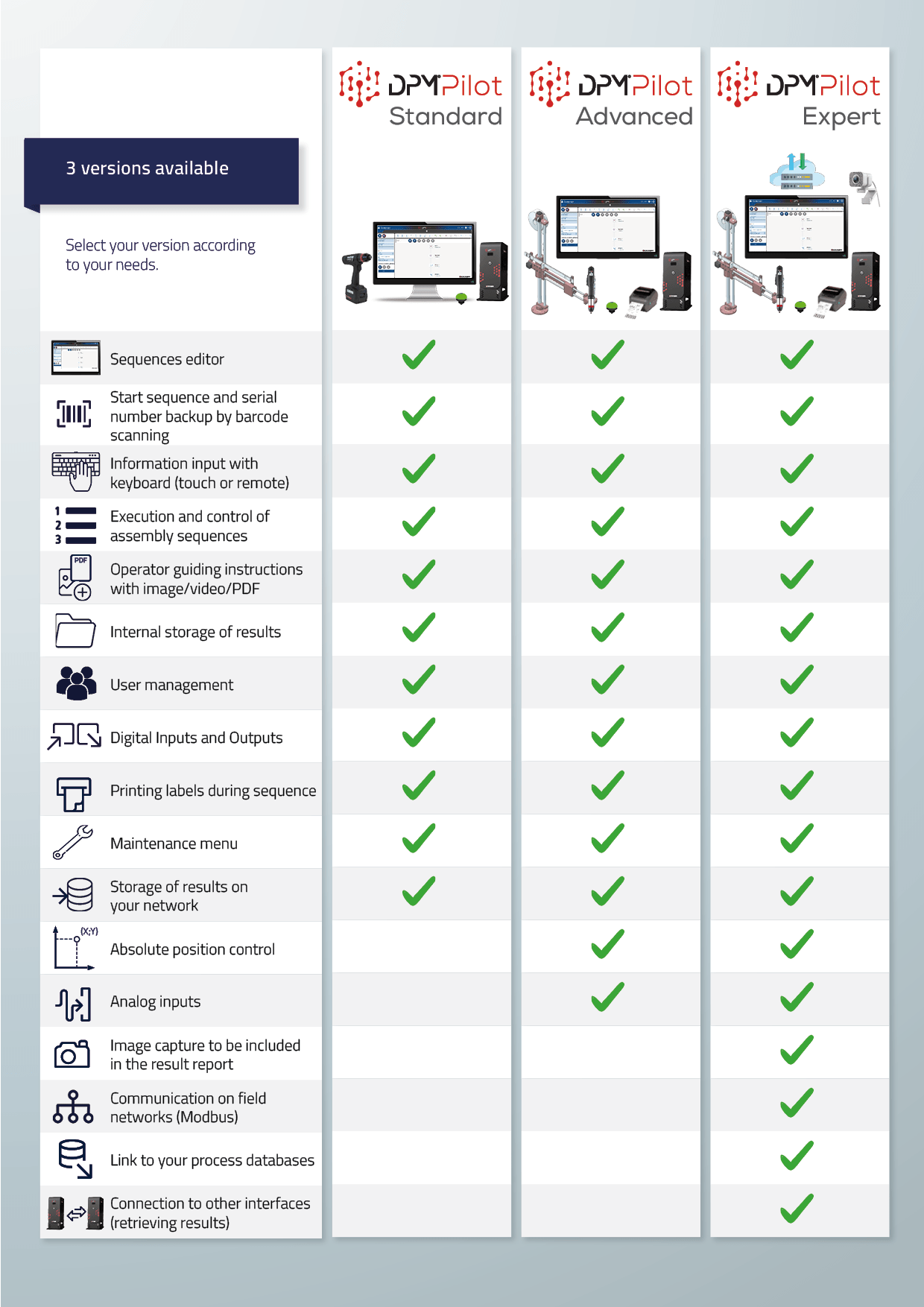

AVAILABLE VERSIONS

• DPM®Pilot Interface

|

|

• DPM®Pilot Interface

|

|

• DPM®Pilot Interface

|

|

Videos

Associated products

DigiLink module for position control management

This module manages position control and analog inputs.

DPM I/O Module

DPM®I/O Module expands the number of additional inputs and outputs.

DPM Wiring Module

DPM®Wiring Module simplifies connection to inputs and outputs of the DPM®Pilot interface.

19-inch industrial HD screen

Non-touch version - code: P200013

BS-5C color ID bit tray

Resources

1Commercial documentation

DPMPilot - Process supervision and traceability smart controller - DOC.60140

- An innovative solution with unique benefits

- Features

- Freed choice of tightening tool brand

- Powerful and intuitive interface

- Available versions

- Versions content

- Optional equipment

2Technical documentation

Process supervision and traceability smart controller DPMPilot - User Manual - DOC.60514

- Information

- Starting-up

- Configuration settings

- Sequence editing

- Production

- Rework

- Results

- Maintenance

- Security

- Standard

- Annexes

- List of revisions

Frequently Asked Questions

If you’d like to upgrade to a higher version of your DPM®Pilot interface, you can order a software extension without changing tyour interface.